Basic Concepts:

At TWR, we are often asked about the different electroless nickel finishes we offer. Our three primary electroless nickel finishes are suitable for many different industrial applications. To better understand the properties and characteristics of these finishes, in order to know which of them are best suited to certain applications, here a few basic concepts:

In general, as Phosphorous content increases, the corrosion resistance of the finish increases as well. However, in this scenario, the hardness of the finish decreases.

As Phosphorous content decreases, the finish becomes harder, but also loses some of its corrosion resistance properties.

Cosmetics & The Electroless Advantage

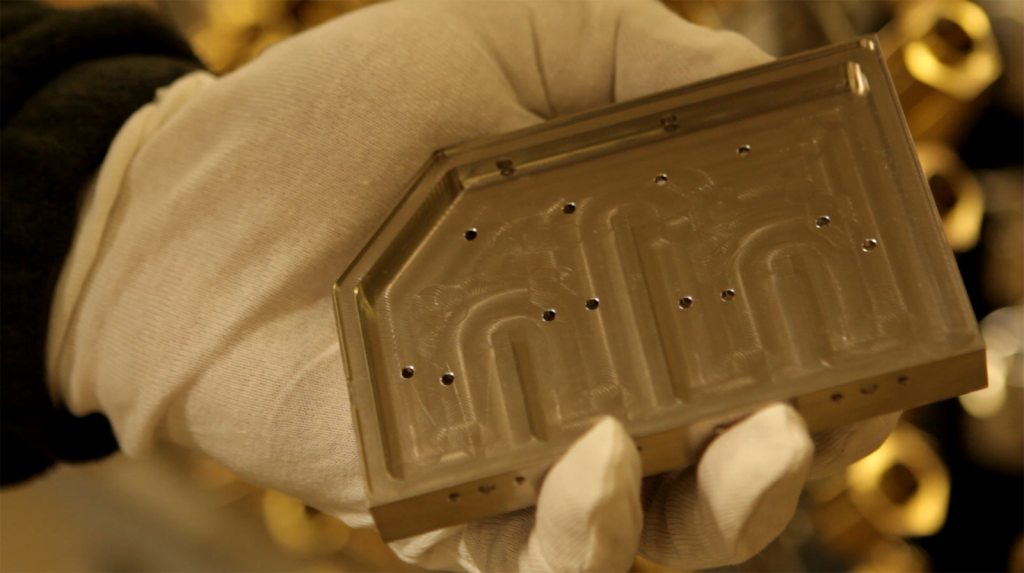

The final cosmetics of our finishes will always mirror that of the base metal. Because of our non-electrolytic plating process, our finishes excel depositing a uniform thickness on all surfaces, including those that are most difficult to reach, such as threads, small holes, recesses and internal areas. This is unachievable in a electrolytic process.

Low Phos

Our Low Phosphorous finish is our hardest and most wear resistant finish. It’s also our least corrosion-resistant finish, but this can be offset by combining the low phosphorous with a high phosphorous underplate. This improves corrosion resistance, while retaining the surface hardness. Our low phosphorous finish is best suited for parts that require a hard surface but that cannot be heat treated after plating.

Mid Phos

Our Mid Phosphorous is our most common electroless nickel finish. Aesthetically it is very bright, with a brilliance comparable to bright electrolytic nickel.

With a harder surface than our High Phosphours finish, our mid-phosphouros retains excellent corrosion resistance. It also has a fast plating rate, making an ideal finish for parts requiring a thicker build-up.

Hi Phos

Our Hi Phosphorous finish is our most corrosion resistant finish. It still retains a fairly hard surface and has the advantage of being heat-treatable with some loss in corrosion resistance. Combined with our electroless plating process, our High Phosphorous finish makes it possible to provide our customers with extreme corrosion resistance for even their most intricate parts.